Description

VG3-640

VG3-540

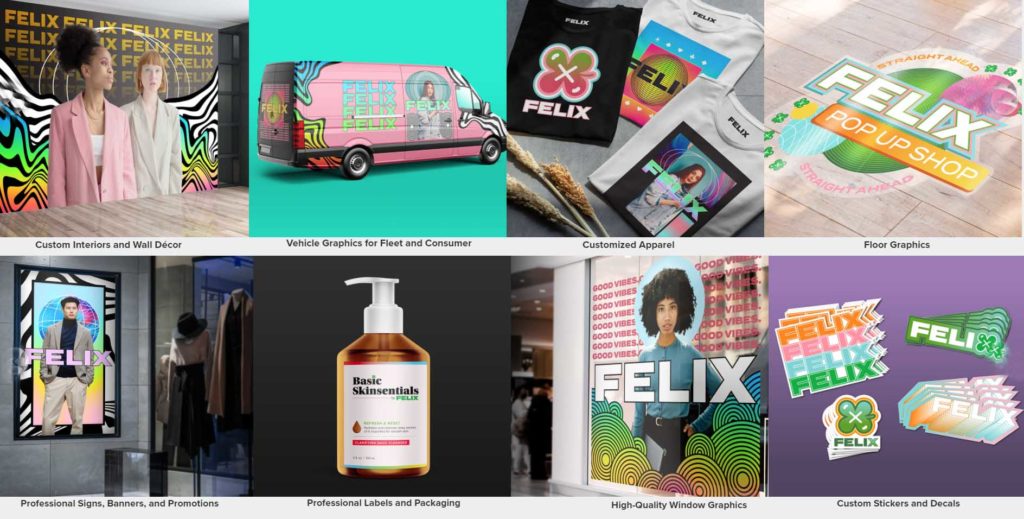

Powering Up Color, Accuracy and Performance on Hundreds of Applications

Next generation VG3 printer/cutters have powered up performance for the most intuitive and efficient TrueVIS machine ever. Easy productivity combined with dynamic ink options, accurate color reproduction, and exceptional print and cut quality makes the VG3 the ultimate choice for building brands and producing the most professional print applications.

Reach New Realms of Color

with True Rich Color and TR2 Inks

TR2 ink is GREENGUARD Gold certified for indoor air quality. It greatly expands your color gamut to offer you new and exciting color output that sets your graphics apart. With the addition of Green and Orange inks and the latest True Rich Color 3 preset in VersaWorks 6, you can reach new areas of color, including purples, reds, greens, and other challenging hues— elevating all your print output with brighter, more detailed color results.

True Color Versatility

with a Variety of Configurations

With Orange, Green, Light Black, and other inks available in new configurations, you can consistently hit very specific Pantone® shades and company brand colors as well as outputting graphics with smooth gradients and skin tones. Not only do new ink configurations offer our widest color gamut yet, but they also provide more choice in your color output with options that include quick color output and a series of options with high intensity color, intensely smooth color, and other complex color choices.

Advanced Print/Cut and Productivity Features

| Automated Pinch Rollers Redesigned inner pinch rollers raise during cutting jobs while outer rollers remain engaged to ensure accurate print and cut operation. | |

| Nozzle Mask Function If a nozzle on the printhead is misfiring, you can minimize printer downtime with the ability to turn off a specific nozzle band to allow continued production. | |

| Custom Crop Improve accuracy on long print runs of stickers and decals using the Crop Mark by Row in VersaWorks 6 software. |

| New Media Holder A one-touch lever locks the media in-place in one easy motion— other easy loading features include an integrated fan to keep the media steady during set-up. | |

| Smart Media Clamps For a more efficient print operation, smart media clamps with integrated grooves don’t interfere with sheet-cutting or need to be removed at any time. | |

| Perforated Sheet Cut Option Reduce post-processing with “easy tear” perforations between print jobs. |

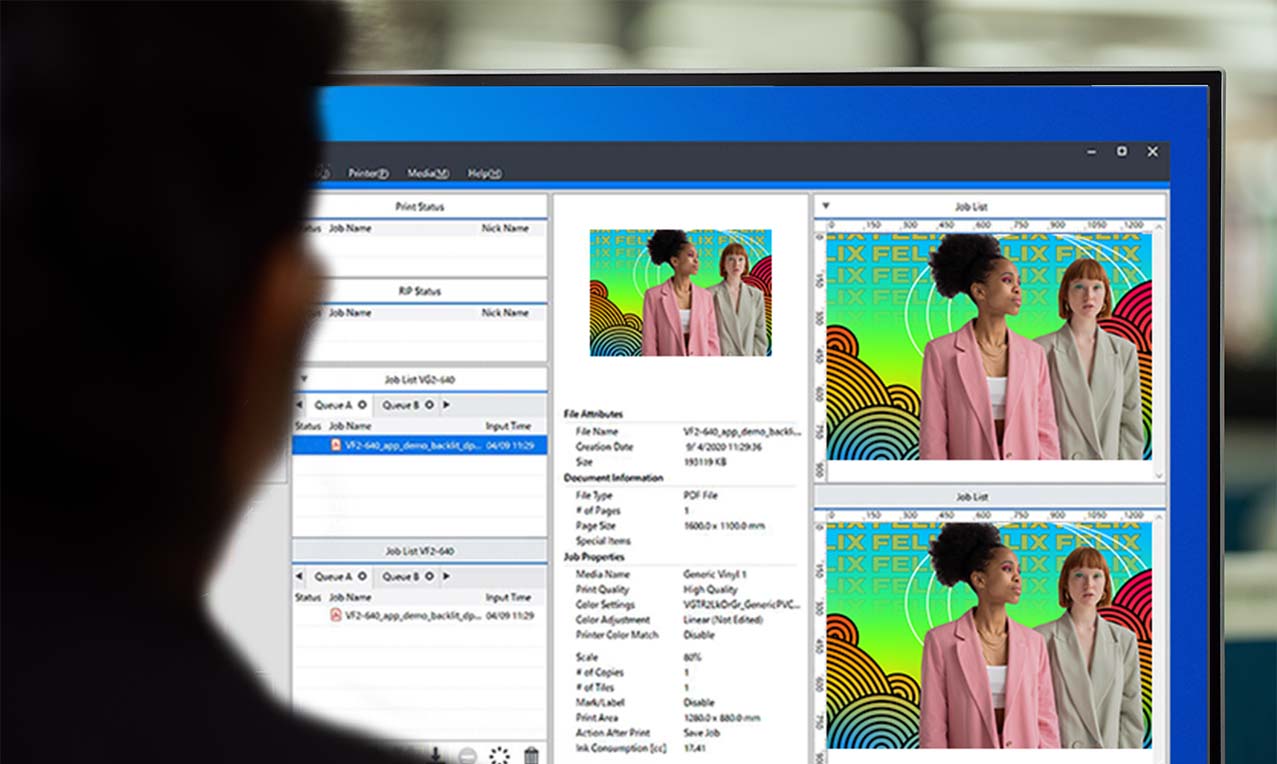

The World’s Most Popular RIP Software Included

- Printer Color Match for multi-device workflows

- Pantone and Roland DG color libraries

- Crop, tile, and nest features

- VersaWorks 6

- Nearest Color Finder for auto color generation

- Create cut lines with PDF design data

- 5 print queues, 5 hot folders

Specifications

TrueVIS VG3 Series

| VG3-640 | VG3-540 | ||

|---|---|---|---|

| Printing Method | Piezo ink-jet method | ||

| Media | Width | 13.2 to 64 in. (335 to 1,625 mm) | 11.7 to 54 in. (297 to 1,371 mm) |

| Thickness | Max. 39.3 ml (1.0 mm) with liner, for printing Max. 15.7 ml (0.4 mm) with liner and 8.6 ml (0.22 mm) without liner, for cutting | ||

| Roll outer diameter | Max. 9.8 in. (250 mm) | ||

| Roll weight | Max. 99 lb. (45 kg) | Max. 77 lb. (35 kg) | |

| Core diameter | 3 in. (76.2 mm) or 2 in. (50.8 mm) | ||

| Printing/cutting width (*1) | Max. 62.9 in. (1,600 mm) | Max. 52.9 in. (1,346 mm) | |

| Ink | Type | TrueVIS INK 500 ml pouch (only white 250 ml) | |

| Colors | Eight colors (cyan, magenta, yellow, black, light cyan, light magenta, light black, and white) Eight colors (cyan, magenta, yellow, black, light cyan, light magenta, light black, and orange) Eight colors (cyan, magenta, yellow, black, light black, orange, green and white) Eight colors (cyan, magenta, yellow, black, light cyan, light magenta, orange, and green) Seven colors (cyan, magenta, yellow, black, light black, orange, and green) Four colors (cyan, magenta, yellow, and black) | ||

| Printing resolution (dots per inch) | Max. 1,200 dpi | ||

| Cutting speed | 0.39 to 11.8 in/s (10 to 300 mm/s) | ||

| Blade force (*2) | 30 to 500 gf | ||

| Blade | Type | Roland CAMM-1 series blade | |

| Offset | 0.0 to 59 ml (0.000 to 1.500 mm) | ||

| Software resolution (when cutting) | 0.98 ml/step (0.025 mm/step) | ||

| Media heating system (*3) | Print heater set temperature: 86 to 113 (°F 30 to 45 °C) Dryer set temperature: 86 to 131 °F (30 to 55 °C) | ||

| Connectivity | Ethernet (100BASE-TX/1000BASE-T, automatic switching) | ||

| Power-saving function | Automatic sleep feature | ||

| Rated input | 100-120/220-240 Va.c. 50/60 Hz 8.0/4.1 A | ||

| Power consumption | During operation | Approx. 1,090 W | |

| Sleep mode | Approx. 50 W | ||

| Acoustic noise level | During operation | 63 dB (A) or less | |

| During standby | 53 dB (A) or less | ||

| Dimensions (Width x Depth x Height) | 113.7 in. x 29.5 in. x 52.0 in. (2,886 mm x 748 mm x 1,320 mm) | 103.7 in. x 29.5 in. x 52.0 in. (2,632 mm x 748 mm x 1,320 mm) | |

| Weight | 448 lb. (203 kg) | 417 lb. (189 kg) | |

| Environment | During operation (*4) | Temperature: 68 to 89.6 °F (20 to 32 °C), humidity: 35 to 80 % RH (no condensation) | |

| Not operating | Temperature: 41 to 104 °F (5 to 40 °C), Humidity: 20 to 80 % RH (no condensation) | ||

| Included items | Dedicated stands, power cord, Media take-up unit, media holders, replacement blade for separating knife, cleaning liquid, drain bottle, User’s Manual, Software(VersaWorks, Roland DG Connect), etc. | ||

- *1 – The length of printing or cutting is subject to the limitations of the program.

- *2 – 500 gf is the maximum instantaneous blade force. The blade force must be adjusted according to details such as the media thickness.

- *3 – Warm-up is required after power up. This may require 5 to 20 minutes, depending on the operating environment. Depending on the ambient temperature and media width, the preset temperature may fail to be reached.

- *4 – Operating environment(Use in an operating environment within this range.)