Description

Application

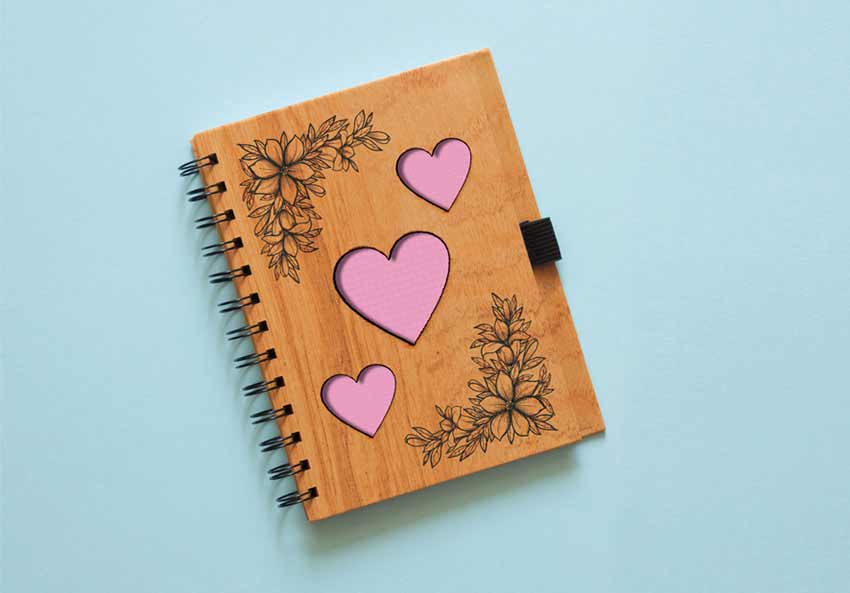

Giftware and Merchandise

GIFTWARE AND MERCHANDISE

Precisely engrave or mark onto smart phone cases, keychains, glass ornaments, pens, notebooks and more. You can also cut-out and engrave your own acrylic and wooden giftware items for print customization with a VersaUV LEF flatbed printer.

Electronics, Leather and Sensitive Items

ELECTRONICS, LEATHER AND SENSITIVE ITEMS

Not just for hard surfaces and robust products, LV laser engravers can add names, photos and messages onto soft surfaces such as leather, cork and fabric products as well as sensitive items like power banks, smart devices, and high-end electronics.

Trophies and Signs

TROPHIES AND SIGNS

Cut-out shapes in wood for trophies, or precisely mark intricate text and designs onto wood, metal and glass. The LV laser engraving machine is ideal for adding 3D reliefs and decorative elements to wooden trophies and signs— combine it with a VersaUV LEF flatbed printer for a complete customization workflow.

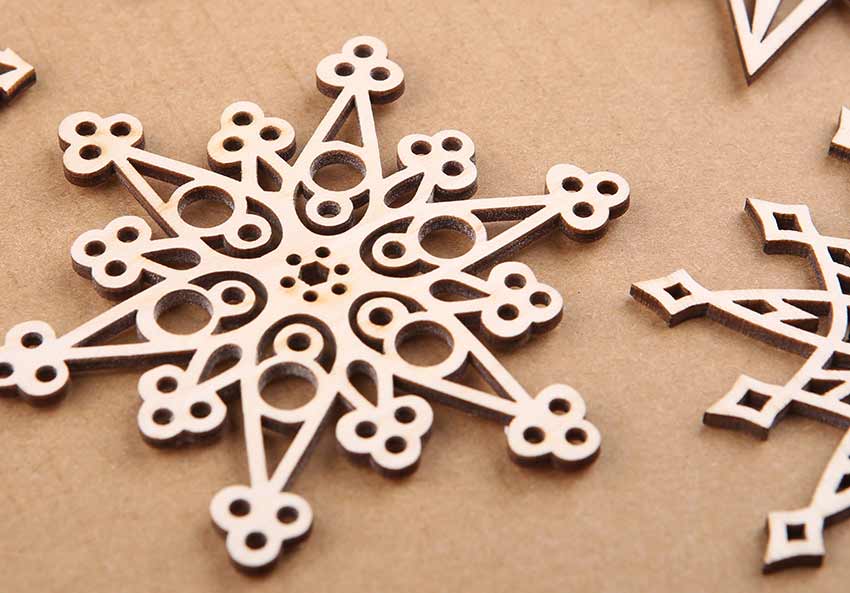

Art and Unique Items

ART AND UNIQUE ITEMS

Cut intricate shapes out of wood, card, and plastic materials to fabricate uniquely brilliant products and prototypes for art projects, games, décor, models and more. Pair your LV laser engraving machine with a VersaUV LEF flatbed printer for the ideal prototyping or giftware solution.

Productivity Features

| Available in two sizes to fit your budget and environment that work with standard wall sockets and require no special electrical set-up. | |

| LV laser-cut surfaces have a smooth, clean finish without burrs— eliminating the need for final touch-up work. | |

| A simple and easy-to-use control panel saves output data for repeat engraving— minimizing the need to return to your computer. | |

| Set-up at the touch-of-a-button with a red laser pointer to automatically set the XY zero point and an auto-focus pin to automatically set the height. |

| An enclosed machine design prevents laser light from escaping and a safety interlock automatically halts laser activation if the cover is opened. | |

| An external LED indicates machine status, while an internal LED light illuminates the work area for safe and easy production. | |

| Comes standard with a Windows driver that can output directly from Adobe Illustrator® and CorelDRAW ®. | |

| The LV-290 model is equipped with a CCD camera that supports material positioning for accurate contour-cutting of UV-printed graphics. |

Engrave, Cut and Build Your Business

with Hundreds of Applications

Interior décor and art

INTERIOR DÉCOR AND ART

Cut intricate shapes out of wood, card, and plastic materials to fabricate uniquely brilliant products and prototypes for art projects, games, décor, models and more.

Giftware

GIFTWARE

Precisely engrave or mark on souvenirs, picture frames, memento boxes, keychains, glass ornaments and more, transforming them into personalised, profitable gift items.

Personalized goods

PERSONALISED GOODS

Laser engrave customer names, photos and messages on leather to create a huge range of personalized products, including water bottle covers, key fobs and more.

Jewellery and fashion accessories

JEWELLERY AND FASHION ACCESSORIES

Mark designs onto coated metal items like watches, tools, bracelets, earrings and rings or engrave onto soft goods like leather purses, bags and fabric products. You can also cut out your own pendants, bracelets and other accessories from leather and acrylic and create stunning cut and engraved wooden jewellery.

Acrylic letters, signs and trophies

ACRYLIC LETTERS, SIGNS AND TROPHIES

Pair your LV with a VersaUV LEF flatbed printer for a complete laser-cutting and print customisation workflow to offer your customers something truly special. Ideal for personalising gifts and promotional items and producing high-end personalised signs and trophies.

Impressive Media Compatibility

The LV series is compatible with an extensive range of materials, from plastics to wood, leather, paper, cork and much more. With two models available featuring different work sizes, you can choose the model that best suits the thickness and size of the materials you want to work with.

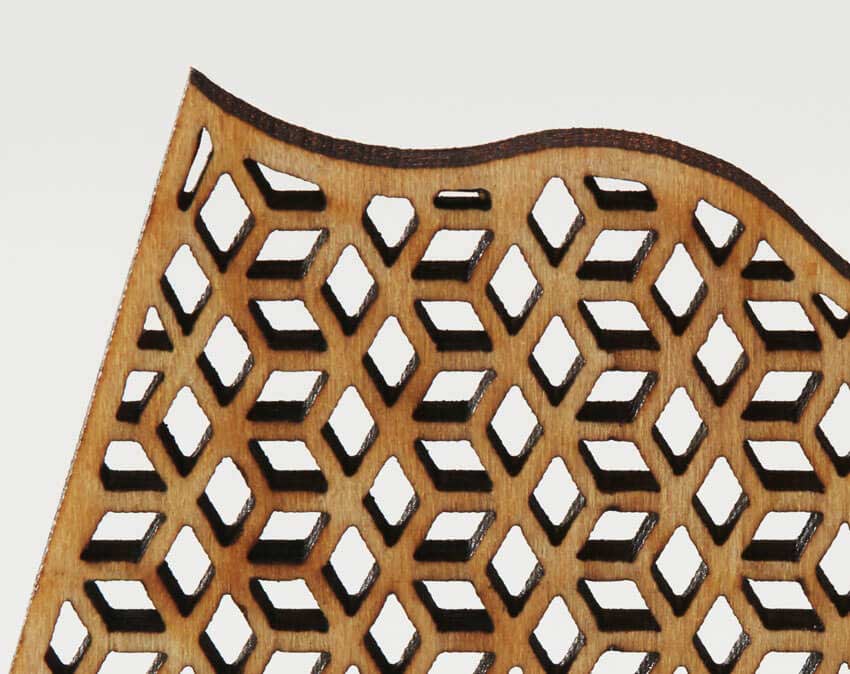

Precision Cutting and Engraving

The LV series uses a non-contact CO2 laser to engrave complex shapes and text with crisp edges at high speed. Unlike conventional computerized engravers, cut surfaces have a smooth, clean finish without burrs, thus eliminating the need for any final touch-up work. With no engraving cutters to break or wear out, the laser always maintains a beautiful finish with no degradation in quality. The LV-290 is equipped with a CCD camera that supports positioning the material to accurately contour cut UV-printed graphics.

Optional Air Compressor to Maintain Your Engraver Effortlessly

Engrave or Mark Cylindrical Objects

The optional rotary devices can easily be added to LV series laser engravers in minutes letting you add details to items like jars, bottles and cans up to 360º.

Create custom bottles and packaging for boutique brands, produce water bottles, cans and mugs, personalise cosmetics containers, gifts and much more.

• Rotary attachment (LV-180 and LV-290)

• Rotary chuck (LV-290 only)

Specifications

| Model | LV-180 | LV-290 | ||

| Dimensions | 30.7 x 29.1 x 16.1 in. (780 x 740 x 410 mm) | 44.2 in x 28.3 in x 39.5 in (1125 mm x 720 mm x 1005 mm) | ||

| Work Area | 18 in × 12 in (458 mm × 305 mm) | With CCD: 21.6 in × 17.3 in (550 mm × 440 mm) | Without CCD: 25.1 in × 18.1 in (640 mm × 460 mm) | |

| Table Size | 20.4 in × 14.7 in (520 mm × 375 mm) | 31.1 in × 20.8 in (790 × 530 mm) | ||

| Max. Part Size (W x L x H) | 19.8 in × 12.1 in × 6.6 in (505 mm × 309 mm × 170 mm) | 30 in × 19 in × 6.4 in (762 mm × 482.6 mm × 165 mm) | ||

| Laser Source | 30W 10.6 µ sealed CO2 Laser | 40W 10.6 µ sealed CO2 Laser | ||

| Cooling | Air-cooled, Operating environment temperature 15°-30°C (60°-86°F) | |||

| Drive | Closed-loop DC Servo Control | |||

| Max. Motor Speed | 40 in/s (1,016 mm/s) | With CCD: 40 in/s (1,016 mm/s) | Without CCD: 60 in/s (1,524 mm/s) | |

| Speed Control | Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) | |||

| Power Control | Adjustable from 0~100% (Up to 16 color-linked power settings per job) | |||

| Engraving Capability | 256-level gray scale image processing capability | |||

| Distance Accuracy | 0.254 mm or 0.1% of move. whichever is greater | |||

| Z-Axis Movement | Automatic | |||

| Interface | Ethernet (10 BASE-T), USB 2.0 | |||

| Compativle Operating Systems | MS Windows | |||

| Resolution | 125, 250, 300, 380, 500, 600, 760, 1000, 1500 dpi | |||

| Focus Lens | Standard: 2.0 in | Option: 1.5 in | Standard: 2.0 in | Option: 1.5/2.5/4.0 in |

| Display Panel | 4-line LCD panel showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus. | |||

| Safety | Class I Laser Product Compliant with EN60825 | |||

| Class II Laser Product Compliant with CDRH | ||||

| 2006/42/EC Machinery Directive Compliance | ||||

| Substrate Base | Honeycomb Table | Aluminum Grid Cutting Table | ||

| Camera System | N/A | SmartVISION Pro CCD (Requires USB Port) | ||

| Facility Requirements | ||||

| Operation Voltage | 100-240VAC, 50-60Hz Auto Switching, Max. 15A | |||

| Fume Extraction | External exhaust system with minimum flow rate 215m3/h (CFM 125 ft3/h) is required, 10kPA negative pressure | |||

| Air Compressor | External Air Compressor needed with a minimum Air flow of 3.18 CFM, Pressure of 49.78 psi, Oil-less, Air Capacity 86-95 L/min | |||